Why Manufacturing Data Without Insights is Like Flying Blind

An insight manufacturing platform is a software solution that turns raw factory data into actionable intelligence. By integrating data from machines, sensors, and business systems like ERPs, it provides a unified view of performance, enabling manufacturers to optimize operations and make data-driven decisions in real-time.

Key capabilities include:

- Real-time monitoring of machine performance, production, and quality.

- Predictive analytics to foresee equipment failures and maintenance needs.

- Data integration to create a single source of truth from disparate systems (MES, ERP, WMS).

- Automated insights that generate recommendations for optimization and cost reduction.

- Scalable deployment via cloud, on-premise, or hybrid solutions.

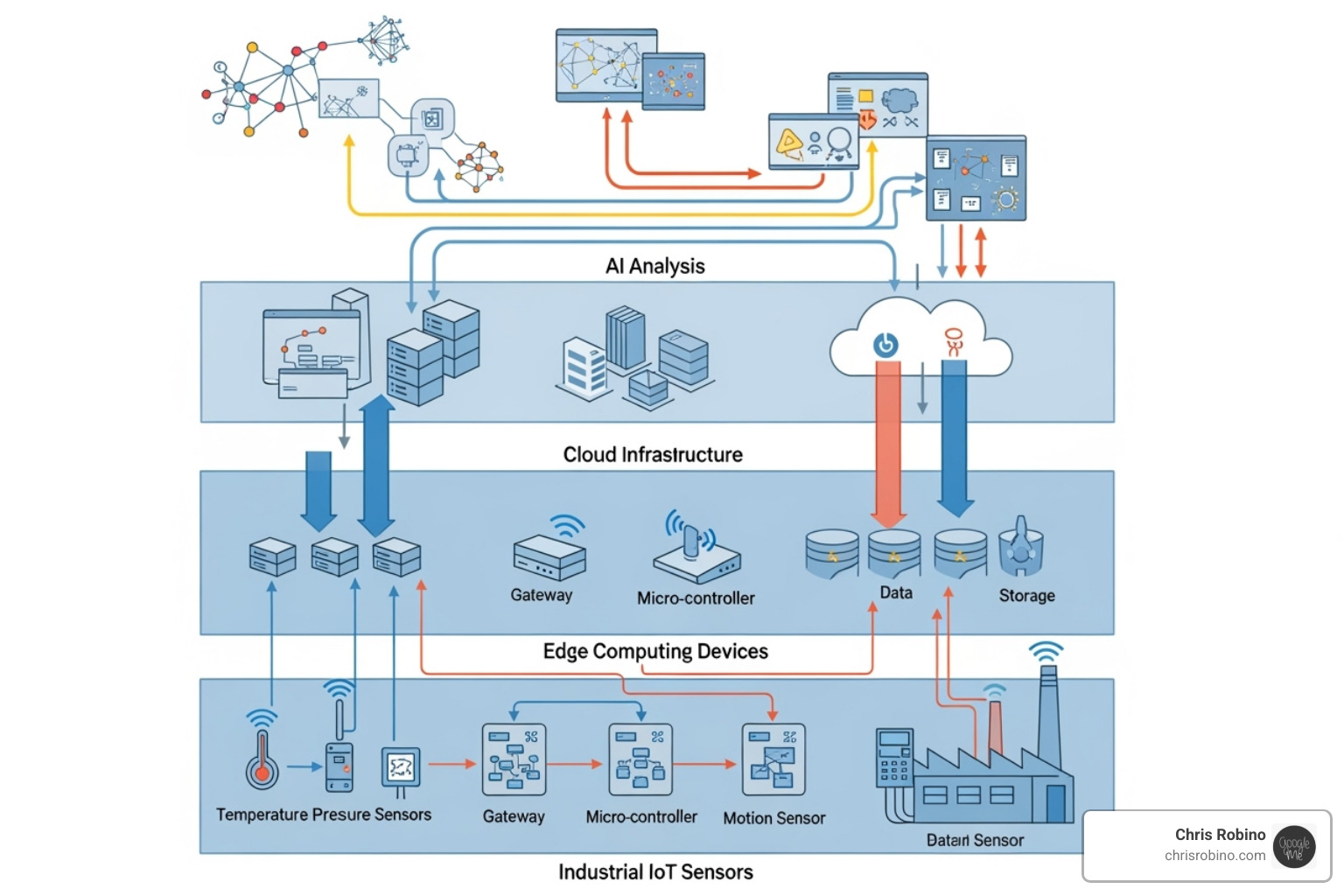

Today’s competitive environment demands proactive, data-driven operations, a dramatic shift from the reactive maintenance of the past. Modern platforms use Industrial IoT (IIoT), AI, and cloud computing to transform factory data into clear guidance, connecting to machine controllers and handling complex data challenges.

I’m Chris Robino, a Digital Strategy Leader with over two decades of experience helping organizations harness AI-driven systems and intelligent search solutions to maximize ROI. I guide companies through digital change, including the implementation of insight manufacturing platforms that deliver measurable business results.

The Technology Powering Modern Manufacturing Insights

An insight manufacturing platform creates a smart factory that can learn, adapt, and optimize itself in real-time. This change is powered by a symphony of technologies working together to turn your facility into a data-driven powerhouse.

The technological foundation includes:

- Industrial Internet of Things (IIoT) sensors: These are the digital eyes and ears monitoring everything from machine status and vibration to temperature, feeding a constant stream of operational data.

- Edge gateways: Located on the factory floor, these devices process data locally, enabling real-time decisions and ensuring operations continue even with intermittent connectivity.

- Cloud platforms: Provide the scalable computational power needed for deep analysis of massive data sets. Our experience with Cloud Solutions for Media highlights the power of cloud infrastructure for managing complex data.

- Artificial Intelligence and Machine Learning: These algorithms analyze the data to spot patterns, predict equipment failures, and suggest optimizations, acting as a 24/7 team of expert analysts. Learn more about how this works at AI-Driven Business Solutions.

- Big data analytics: These tools present complex intelligence in clear, actionable dashboards and reports for everyone from operators to managers.

How Data Becomes Actionable Intelligence

The journey from raw data to valuable insight follows a sophisticated path.

- Data Ingestion: The platform connects to machine controllers using standard protocols like MTConnect and OPC UA, the universal languages that allow diverse equipment to communicate. Specialized connectors also bring legacy equipment online.

- Processing and Standardization: Manufacturing data is often messy—arriving late, missing, or out of order. The platform cleans and standardizes this data into a consistent model, allowing for accurate comparisons across machines, lines, and facilities.

- Advanced Analysis: AI algorithms and proprietary intelligence engines analyze the standardized data to identify “units of work” and assess their efficiency. Pattern recognition spots anomalies that signal potential problems or opportunities.

- Actionable Intelligence: The final result is predictive maintenance alerts, automated recommendations, and intuitive dashboards. Instead of drowning in data, you get clear guidance to optimize schedules, reduce waste, and improve effectiveness. This evolution, as seen in our work Moving from Ops System to Browser-Based to the Clouds, creates resilient and responsive operations.

The Core Components of an Insight Manufacturing Platform

An insight manufacturing platform acts as the conductor for your factory, changing disparate data points into a harmonious, intelligent system. Its modular design allows it to be configured to your specific needs, whether for a small job shop or a global enterprise.

At its core, the platform is built on:

- A robust data foundation: This system transforms messy, unstructured data from the factory floor into a standardized, meaningful format.

- A centralized data hub: This serves as the single source of truth, bringing all operational information together in one secure, accessible location.

- An analytics engine: Powered by AI and machine learning, this is the brain of the operation, constantly analyzing data to find patterns and predict outcomes.

- Visualization tools: These present complex intelligence through intuitive dashboards and reports that enable faster, better decision-making.

Core Modules Explained

The platform’s power comes from integrated modules that work together seamlessly:

- Manufacturing Execution System (MES): Provides real-time visibility into shop floor activities, tracking cycle times, downtime, and quality to optimize production.

- Enterprise Resource Planning (ERP) Integration: Connects production data with business systems to create a complete picture of how performance impacts the bottom line.

- Warehouse Management System (WMS): Streamlines logistics with real-time material tracking and automated inventory processes.

- Quality Management System (QMS): Automates inspections and quality tests, enabling rapid root cause analysis of any issues.

- Supply Chain Management (SCM): Offers real-time insights into supplier performance and potential disruptions, improving visibility across the supply network.

These modules create a connected manufacturing ecosystem. As we explore in our Optimize Everything approach, true optimization happens when all pieces work in harmony.

What is the purpose of an insight manufacturing platform?

The platform’s core purpose is to open up the hidden value in your manufacturing data. It achieves this by:

- Breaking down data silos: It connects separate systems (machines, ERP, QMS) that don’t normally communicate.

- Creating a single source of truth: Ensures everyone works from the same accurate, real-time information.

- Empowering a connected workforce: Gives operators, engineers, and managers the data they need to excel.

- Enabling holistic operational visibility: Provides a big-picture view of how different processes connect and affect each other.

- Driving continuous improvement: Delivers constant performance data and actionable insights, making improvement a daily practice.

The Tangible Benefits: Driving ROI in Your Factory

Investing in an insight manufacturing platform is a strategic decision that directly impacts your bottom line. The platform creates a ripple effect of improvements, turning better data into smarter decisions and measurable financial results.

Key benefits include:

- Increased efficiency: Real-time visibility exposes bottlenecks, improves machine utilization, and smoothes workflows, leading to higher production rates.

- Improved quality control: Continuous monitoring catches deviations as they happen, improving first-pass yield and enabling rapid root cause analysis to prevent future defects.

- Reduced operational costs: Predictive maintenance prevents expensive emergency repairs, while data analysis helps optimize energy consumption and lower inventory carrying costs.

- Improved flexibility and agility: Data-driven insights allow you to adapt quickly to market shifts, raw material price changes, and new customer demands.

- Sustainability improvements: By tracking resource consumption (energy, water, materials), you can make targeted reductions in waste and emissions, which often saves money. Our approach to sustainable growth, detailed in our Good to Grow content, aligns with these long-term benefits.

Real-World Applications and Outcomes

These platforms solve practical problems that manufacturers face daily:

- CNC milling optimization: The platform analyzes data on speeds, feeds, and tool wear to suggest optimal cutting parameters, reducing cycle times and extending tool life.

- Predictive maintenance for hydraulic units: By monitoring vibration and temperature, the system detects anomalies that signal impending failure, allowing for planned repairs instead of costly shutdowns.

- Reducing scrap and rework: The system flags process deviations in real-time, allowing operators to correct issues before they result in defective parts.

- Improving on-time delivery: Real-time production tracking provides early warnings of potential delays, allowing managers to adjust schedules and maintain customer commitments.

- Automating inventory and procurement: AI-powered algorithms analyze consumption patterns to optimize ordering, reducing carrying costs and preventing stockouts.

Companies using these platforms regularly report these kinds of improvements by moving from reactive problem-solving to proactive optimization.

Implementation and Integration: Making It Work for You

Implementing an insight manufacturing platform involves connecting all your existing systems to work in harmony. The platform doesn’t replace your MES, ERP, or WMS; it acts as a universal translator, creating a unified data highway.

This is achieved through flexible connectors, SDKs, and open APIs that pull data from every source. Even legacy equipment can be connected using specialized IoT Connectors, extracting valuable data without expensive retrofits. This creates the “single source of truth” that large enterprises need to standardize operations.

When it comes to deployment options, you have choices:

- Cloud: Offers maximum scalability and reduces the IT burden.

- On-premise: Keeps all data and infrastructure under your direct control.

- Hybrid: Combines the benefits of both, keeping critical real-time operations on-site while using the cloud for heavy analytics.

Data security and governance are paramount. A robust platform must include secure data ingestion, encryption, access controls, and threat detection to protect your valuable manufacturing data. The role of partners and APIs is also crucial, providing an ecosystem of integrations that extends the platform’s capabilities. Our experience with Cloud Solutions for Media shows how vital these partnerships are for successful digital changes.

How to choose the right insight manufacturing platform for your needs

Choosing the right platform requires a clear strategy:

- Assess your current challenges: Start by identifying your biggest pain points, such as unplanned downtime, quality issues, or missed deadlines. Let these problems guide your search.

- Define clear objectives with measurable KPIs: Instead of a vague goal like “better efficiency,” aim for something specific, like “reduce unplanned downtime by 25%.” This creates a clear scorecard for success.

- Evaluate scalability: The platform must be able to grow with your business, from a single facility to a global network, without requiring a complete overhaul.

- Consider vendor support and training: A strong partnership with a vendor who provides comprehensive training and ongoing support is critical for long-term success.

- Plan for a phased rollout: Start with a pilot program on a single production line or in one facility. This approach minimizes risk and allows you to learn and adjust before expanding.

Frequently Asked Questions about Insight Manufacturing Platforms

Here are answers to common questions manufacturers have when exploring insight manufacturing platforms.

How does an insight platform differ from a traditional ERP or MES?

Think of your ERP and MES as systems of record. An ERP handles business records (finances, orders), telling you what happened in the past. An MES manages shop floor activities (work orders, production tracking), telling you what’s happening now. They are excellent at storing information.

An insight manufacturing platform is a system of intelligence. It integrates and analyzes data from your ERP, MES, machines, and sensors to understand why things are happening and predict what will happen next. It moves beyond historical reports to provide predictive and prescriptive insights, connecting data across silos to deliver true operational visibility.

What kind of data does an insight manufacturing platform collect?

The platform captures a complete picture of your operations by collecting data from multiple sources:

- Machine Data: Real-time status (running, idle, alarm), performance metrics (spindle load, speed), cycle times, part counts, and diagnostic codes.

- Sensor Data: Information from additional IIoT sensors, such as vibration, temperature, and power consumption, to monitor equipment health and environmental conditions.

- Quality System Data: Defect information, dimensional measurements, and test results from both automated and manual inspections.

- MES/ERP Data: Contextual information like work orders, production schedules, inventory levels, and bill of materials.

- Operator Input: Manual entries for process parameters, notes on machine issues, and rework tracking, capturing valuable human expertise.

How does this technology support specific processes like CNC milling?

For a process like CNC milling, an insight manufacturing platform provides targeted value:

- Real-time Monitoring: It connects directly to CNC controllers to track machine status, axis positions, and spindle load, allowing for immediate issue identification.

- Process Optimization: By analyzing data on tool wear, material removal, and cycle times, the platform helps fine-tune operations for faster production and longer tool life.

- Predictive Maintenance: It analyzes vibration and temperature data to predict failures in critical components like spindles and drives, enabling proactive maintenance.

- Automated Tracking: The platform automatically captures accurate part counts and cycle times, eliminating manual tracking and improving data for costing and scheduling.

- Downtime Reduction: By identifying patterns in setup issues and machine anomalies, it helps streamline processes and minimize non-productive time.

Conclusion: Building Your Factory of the Future

The factory of today is becoming smarter and more connected, driven by the insight manufacturing platform revolution. What once seemed like science fiction—machines that predict their own maintenance needs and production lines that optimize themselves—is now a reality for competitive manufacturers.

These platforms transform raw data into actionable intelligence, serving as the central nervous system for your entire operation. For large companies, this means standardizing operations, optimizing global supply chains, and achieving excellence at scale.

The future of manufacturing is intelligent and connected. Smart factories use AI and real-time data to move beyond reactive problem-solving to proactive optimization. An insight platform is the brain of the modern factory, learning from patterns to suggest improvements that drive real business results.

The journey starts by identifying your key challenges. What would predictive maintenance or better supply chain visibility mean for your business? Companies that accept these technologies are building a durable competitive advantage.

For expert guidance on integrating these advanced technologies and open uping the full potential of your manufacturing intelligence, our team is here to help. We understand the complexities of digital change and can help you steer this exciting evolution.

Ready to build your factory of the future? Let’s Get to Work together and turn your manufacturing vision into reality.